Salt Spray Test For Zinc Plating

Salt spray test for zinc plating. The American Society for Testing Methods. Salt spray testing is a means to measure the relative protective value of a particular finish. Xray adhersion salt spray testing and black zinc plating.

All testing is done in accordance with ASTM-B-117. If I check 6 month old zinc plated product is there any chances of getting white rust for same salt spray test for 48 hours. Zinc plating is the basic process of protective coating to protect the substrate from coating.

Shankar Khandelwal - Coimbatore Tamilnadu INDIA. This test and also Kester-. ZINC PLATING 101 Zinc Plating The Corrosion-Prevention Workhorse.

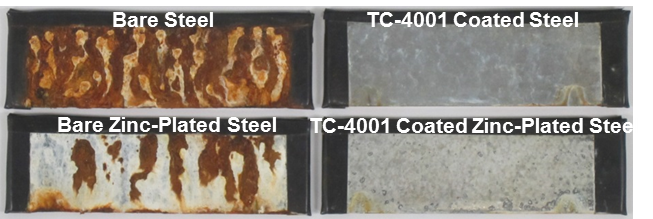

A final thought is that zinc alloys like zinc-iron zinc-nickel and tin-zinc are more corrosion resistant than plain zinc and may be appropriate for the part in question. Dear experts We are producing hot rolled steel sheet metal part with zinc plating. Salt spray tests are used on phosphate surfaces zinc and zinc-alloy plating electroplated tin copper nickel and chromium organic coatings paint coatings and coatings that arent applied electrolytically.

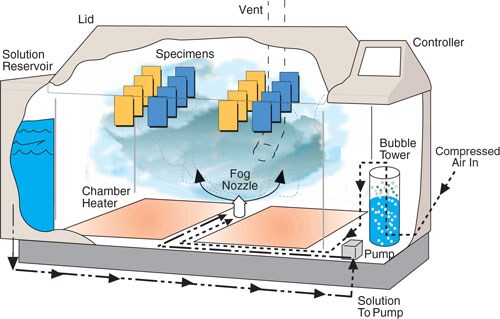

The Salt Spray Test uses a 5 salt solution dissolved in water that is sprayed over the parts in a closed cabinet. Sulfur Dioxide ASTM B605. So unless your part averages 150 hours in salt spray on average half your parts will fail and half your parts will get to 96 hours and above.

The component is subjected to salt spray test in a salt fog chamber usually in plastic coated chambers for hours. By rigidly controlling the exposure environment a value can be derived to measure when corrosion starts. The key word is relative.

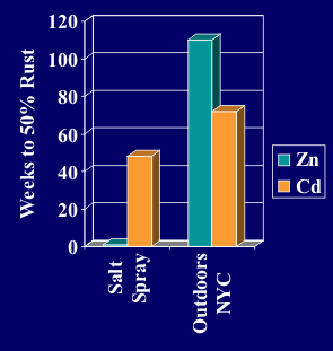

To enhance corrosion lifethe plated and passivated component is subjected to top coats like HyProCoat 330. The correlation was developed for prediction of corrosion occurrence time of zinc plated steel using accelerated corrosion factors.

Link to spec at Techstreet.

If you wanted some chromated zinc-plated parts to pass 96 hours in salt spray to white rust the exact same part is expected to reach anywhere between 61 and 131 hours if placed in two different chambers. Minimum times are 72 hours with no white corrosion products and 168 hours with no red corrosion products. A final thought is that zinc alloys like zinc-iron zinc-nickel and tin-zinc are more corrosion resistant than plain zinc and may be appropriate for the part in question. And thats why we put them through our state-of-the-art salt fog chamber in accordance with ASTM B117. Testing the Corrosion Resistance of Zinc Coatings Some metal finishing shops have the capability to test the corrosion resistance of a zinc-coated surface after plating. Link to spec at Techstreet 96 hours no white rust or red rust. By rigidly controlling the exposure environment a value can be derived to measure when corrosion starts. This is typically performed by a process known as salt spray testing. This test and also Kester-.

For zinc -and cadmium plated parts and for anodized aluminum this is specified as first sign of white corrosion For steel-based samples it is the first sign of red. So if you hear that someone elses testing chamber is as good as ours we suggest you take it with a grain of salt. The correlation was developed for prediction of corrosion occurrence time of zinc plated steel using accelerated corrosion factors. For zinc plating we are conducting Neutral salt spray test for each batch as per ISO 9227 affil. Wolverine Plating Company specializes in barrel plating services including barrel zinc plating zinc electroplating zinc nickel plating thickness services at wolverine plating. The key word is relative. So unless your part averages 150 hours in salt spray on average half your parts will fail and half your parts will get to 96 hours and above.

Post a Comment for "Salt Spray Test For Zinc Plating"